When do you need STT technology?

Thanks to the numerous advantages, offered in terms of quality and reliability (reduction of production times and cleaning operations and consequent increase in productivity), STT surface coatings can be used in various application areas.

Plastics materials

Non-stick and smoothness are essential in a delicate sector such as plastic processing. STT products are ideal for the internal coating of tanks, containers, molds and other equipment, even large ones. The coated surfaces are easier and faster to clean and more hygienic and safe for the working environment, given the drastic reduction in the use of chemical release agents

Mechanics

There are several coatings designed specifically for the mechanical sector. In this context the action of dry lubrication and anti-friction is extremely important, in particular for elements such as rings, bushings, bolts, chains, tie rods, screws, etc. but also for more complex components such as transmission parts, pistons, gears, connecting rods, cams, pumps and valves, various sliding mechanisms and parts of machine tools.

Thermo-hydro-sanitary systems

The application areas of the STT coatings also include the treatment of various thermo-hydro-sanitary products, for which it is possible to reduce the friction and non-stick effects caused by the formation of limestone.

Petrochemical

The main characteristics that provide the multiple coatings for the petrochemical sector, are corrosion protection and reduction of static and dynamic friction coefficients. In particular, components of male or ball valves, screws, tie rods and bushes are treated.

Automotive

The automotive industry can take advantage of the advantages offered by STT coatings in various areas: in particular for the reduction of friction of mechanical elements and for the coating of body parts for aesthetic issues.

Packaging

Many machines and equipment used in the packaging sector are facilitated by the flow and detachment properties of STT products: conveyors, packaging machines.

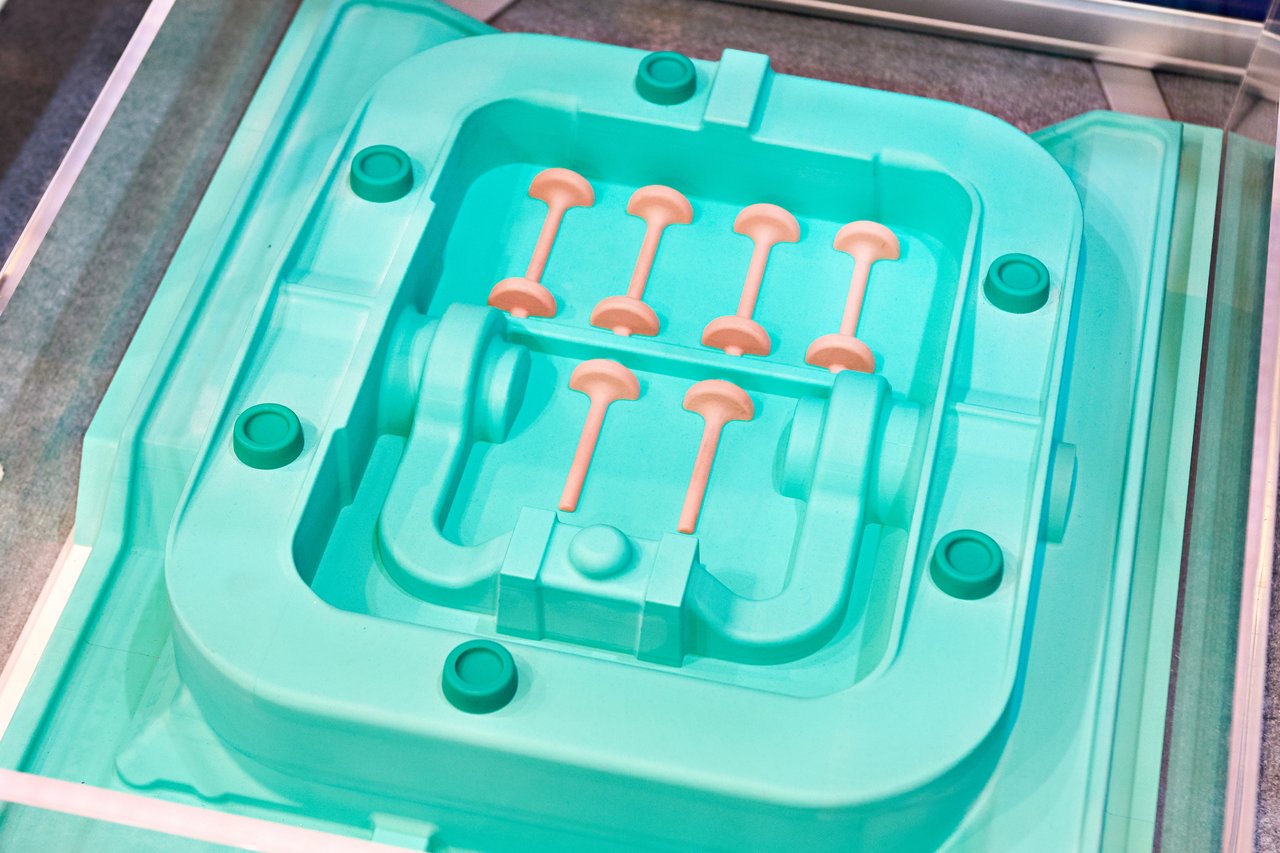

Rubber

STT products for the coating of molds and rubber processing equipment, allow a considerable reduction of maintenance time, STT products for the coating of molds and rubber processing equipment, allow faster maintenance, allow faster cleaning and reduce processing waste, ensuring high non-stick and smoothness.

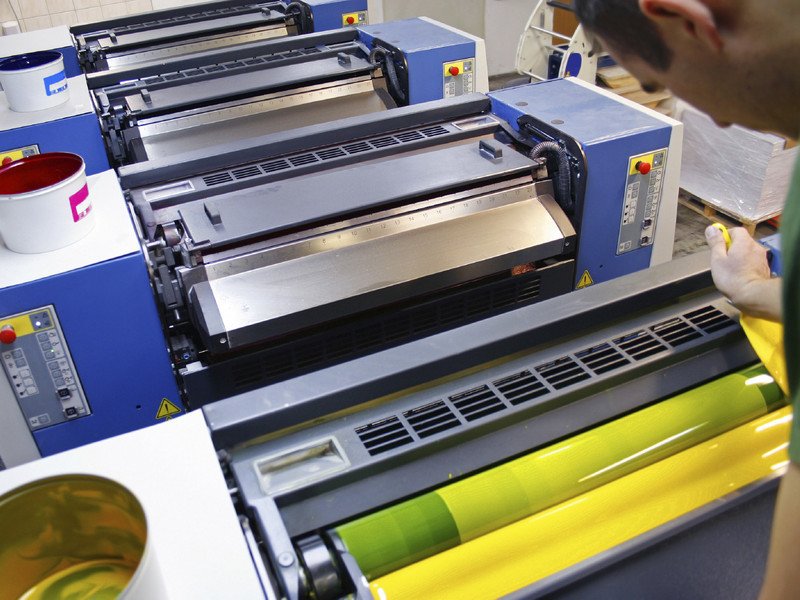

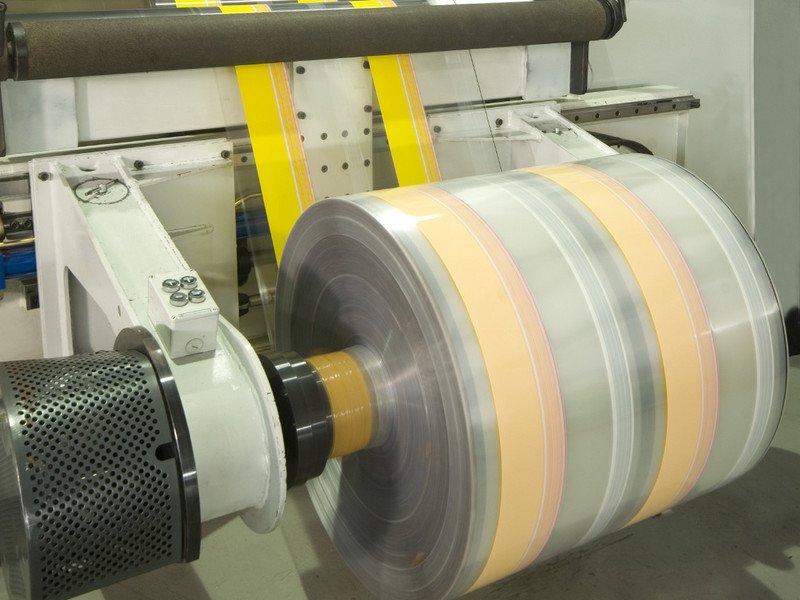

Graphic industry

STT coatings offer advantageous solutions for the maintenance of printing systems, allowing the reduction of production costs, instead of a higher performance thanks to the reduction of downtime.

Industrial painting

With STT coatings, painting operations become more efficient. Smoother surfaces and easier cleaning result in reduced processing times and higher productivity.

Food processing

Several food processing machinery can be coated with STT products, increasing productivity, reliability, safety and hygiene in processing processes. The surfaces of machines for working pasta, cheeses and other foods offer the necessary non-stick, smoothness and detachment characteristics that increase productivity by reducing cleaning and maintenance times.

Fabric processing

Coatings characterized by maximum non-stick and easy sliding of processed products. Extremely easy cleaning of processing scraps, resistance to the corrosive action of chemical products. STT products guarantee these characteristics on the surfaces of equipment and plants for the processing of fabrics and non-woven fabrics, in particular dye tanks, conveyors, etc.

Wood processing

Thanks to the non-stick coating of various components, wood processing achieves a significant increase in productivity, a reduction in production costs and a reduction in maintenance and cleaning times.